Model No.︰9300

Brand Name︰Lenze

Country of Origin︰Germany

Unit Price︰-

Minimum Order︰1 pc

| 9300 servo inverter | ||

The 9300 family provides extensive interface equipment, regardless of the software version: - Analog/digital I/Os The default feedback system uses a resolver, but an incremental or absolute encoder system could also be connected to function as an alternative motor feedback system or an additional position encoder system. |

Complete positioning control with sequence control is integrated in the 9300 servo positioner. Positioning technology is made easily accessible even to less experienced users, thanks to a simple commissioning process and few input values. The uniform block structure of up to 32 program blocks speeds up the creation of positioning sequences.Even demanding positioning tasks can be performed using the supplementary functions, such as override, velocity changeover and mark-controlled target correction. Of course, basic functions, such as homing and manual control, form part of the basic functional scope. |

| 9300 servo cam profiler | ||

Set-up costs can be reduced considerably by using the 9300 servo cam profiler. Up to eight different cams can be saved in the drive, so that you can switch between them during production without delay. The extension and compression of the cams means that they can easily be fine-tuned to suit the process.In order to achieve consistent weld seam quality, a special function for opening and closing a welding bar has been integrated into the cam profiler: If the line speed is variable, a constant welding time can be achieved in wide ranges. |

The expense and effort that is usually involved in project planning and programming can be cut significantly by using the 9300 servo register controller’s preconfigured technology function. The integrated register controller keeps aligning the angular position of draw-in rollers, impression cylinders, slitting rollers or other machining stations with the print image. Second printings, cuts, perforations, embossing, joints, etc., are always exactly where they should be. Drifts become a thing of the past and product quality increases – all without using a higher-level control or a speed superimposition gearbox. |

Specifications︰

9300 servo inverter

The intelligent drive for modular machines

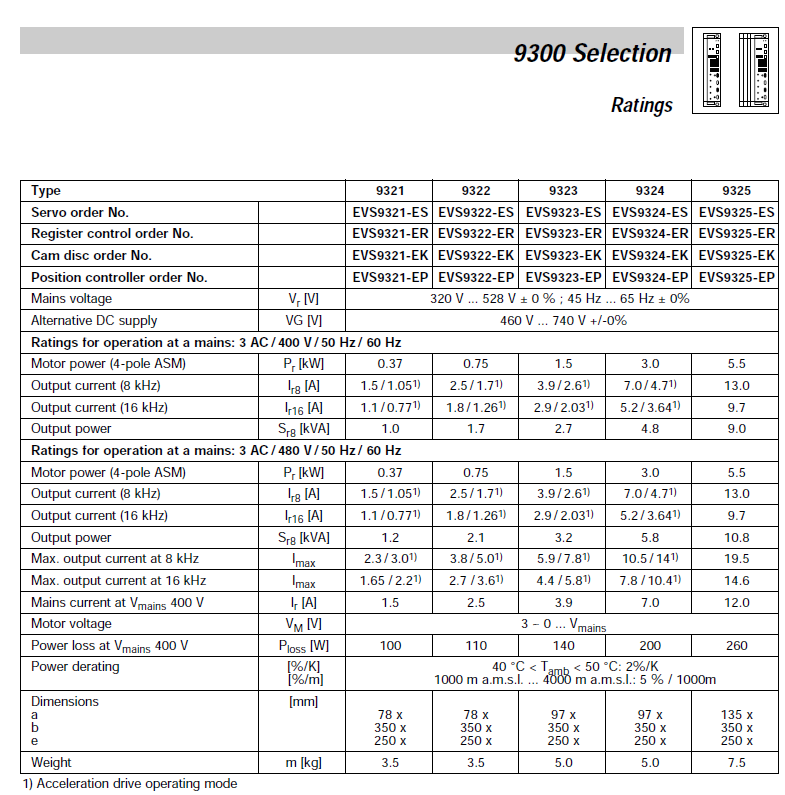

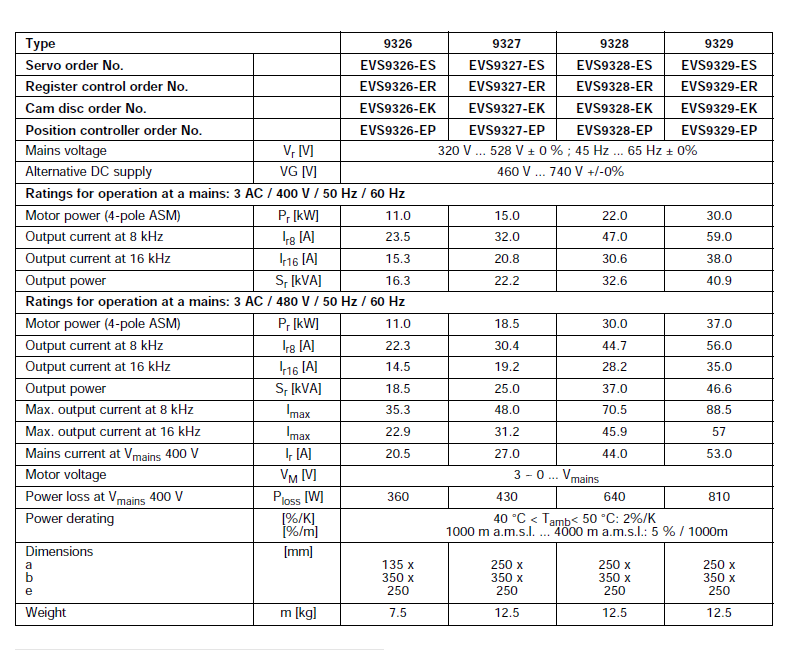

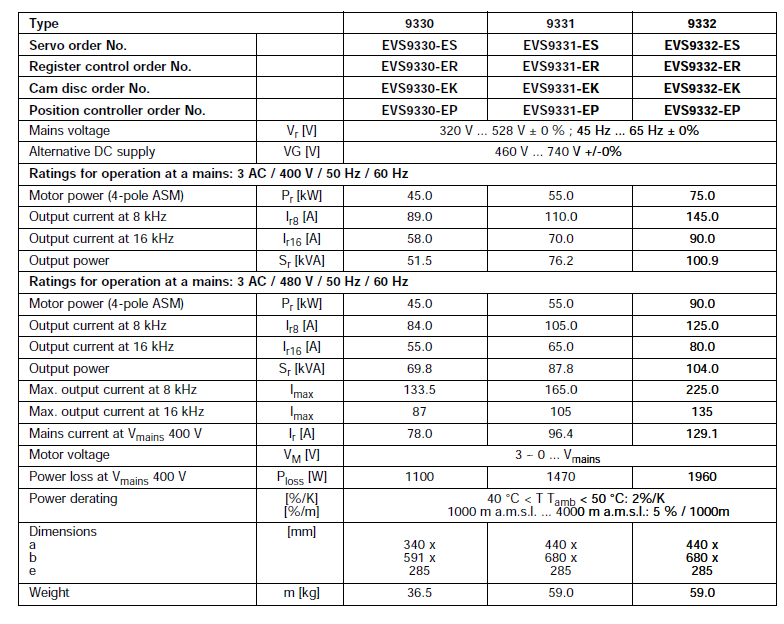

9300 intelligent drives are ideally suited to the independent control of subprocesses within a machine. Taking existing standard applications as a starting point, individual drives can easily be extended with the help of function blocks that can be interconnected as desired; this takes the pressure off the central control and facilitates modular mechanical engineering. The series can be used universally in the power range 0.37 to 75 kW.

In order to meet the most diverse servo technology requirements, four software versions are available:

9300 servo drive

9300 servo positioner

9300 servo cam profiler

9300 servo register controller

By using a uniform user interface, the need for training is reduced – once you have learned how to use it, this knowledge will never go to waste. 9000 servo drives can be integrated into current fieldbus systems easily using the pluggable AIF communication module.

The devices are optionally available with the integrated "safe torque off" (safe standstill) function.

A large number of system accessories finish off the entire product range.

Min Order︰ 1

Standard Met︰ UL VDE CE